Visual Inspection is the oldest simplest, fastest, economical and most commonly used test for detecting defect on the surface of the weld, plate, pipe, turbine, heatexchangers and boilers.

Inspection may be carried out direct by the use of the naked eye or can be enhanced by using optical systems such as magnifiers and other visual examination aids or indirect by the use of A variety of equipments are available for visual examination including mirrors, video scopes etc.

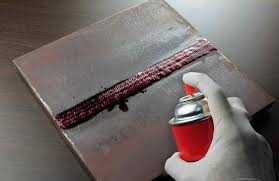

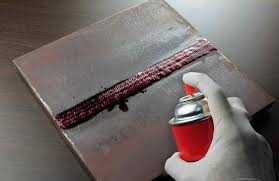

Liquid penetrant testing is a nondestructive means of locating open to the surface discontinuities based on capillary action surface tention and wettability.

Is a non-destructive testing (NDT) process for detecting surface and subsurface discontinuities in ferroelectric materials such as iron,

nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part.

Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements.

Ultrasonic inspection can be used for flaw detection/evaluation, dimensional measurements, material characterization, and more.

To illustrate the general inspection principle, a typical pulse/echo inspection configuration as illustrated below will be used.

Radiographic inspection is based on the exposure by a radioactive source (Ir-192) that can be used as a source of photons. Since the amount of radiation emerging from the opposite side of the material can be detected and measured, variations in this amount (or intensity) of radiation are used to determine thickness or composition of material.